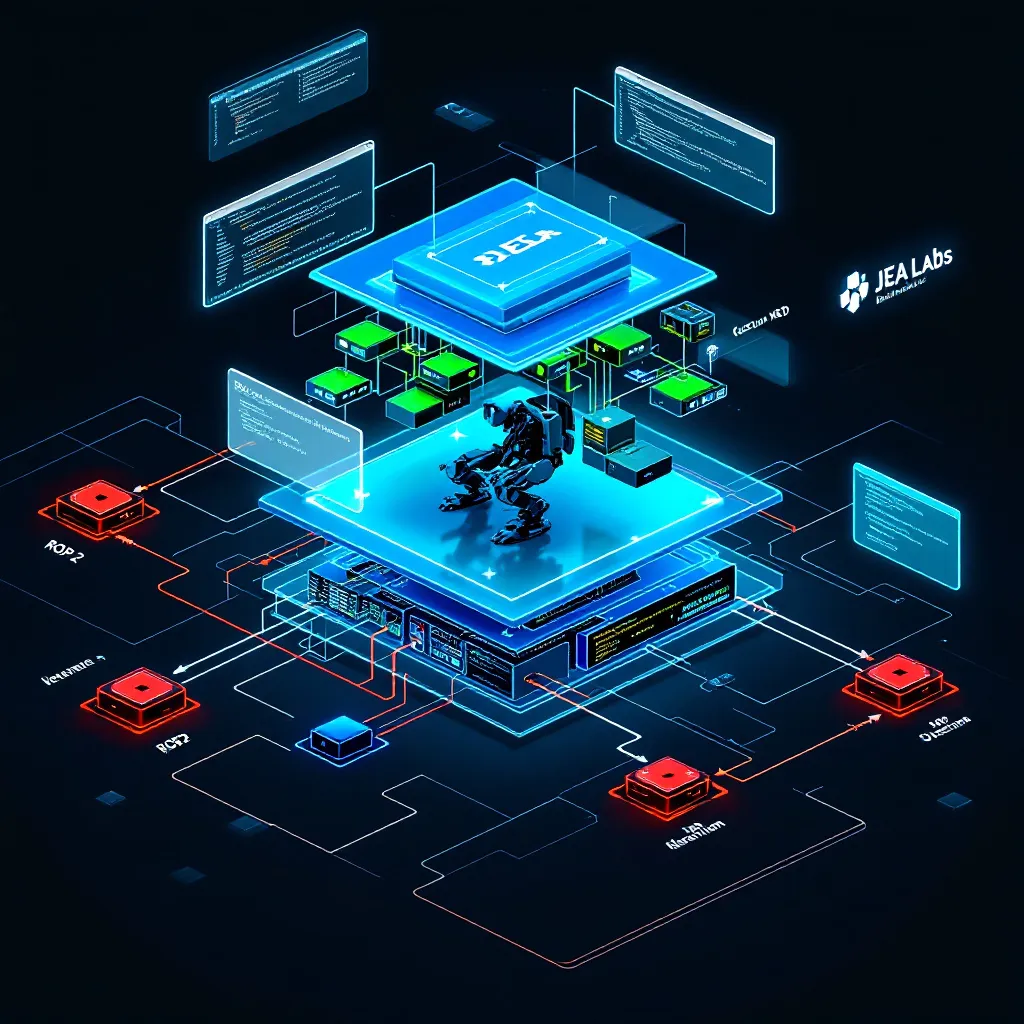

The Computational Bottleneck in Modern Robotics

Throughout our Robotics Anatomy series, we've examined the evolving landscape of industrial automation, component integration challenges, supply chain complexities, and future trends. But one critical bottleneck remains at the heart of advanced robotics development: computational power.

Modern robotics systems—from autonomous factory robots to surgical assistants and humanoid interfaces—all face the same fundamental limitation. The increasing sophistication of sensors, actuators, and AI algorithms demands exponentially greater computational resources that traditional computing architectures simply cannot deliver.

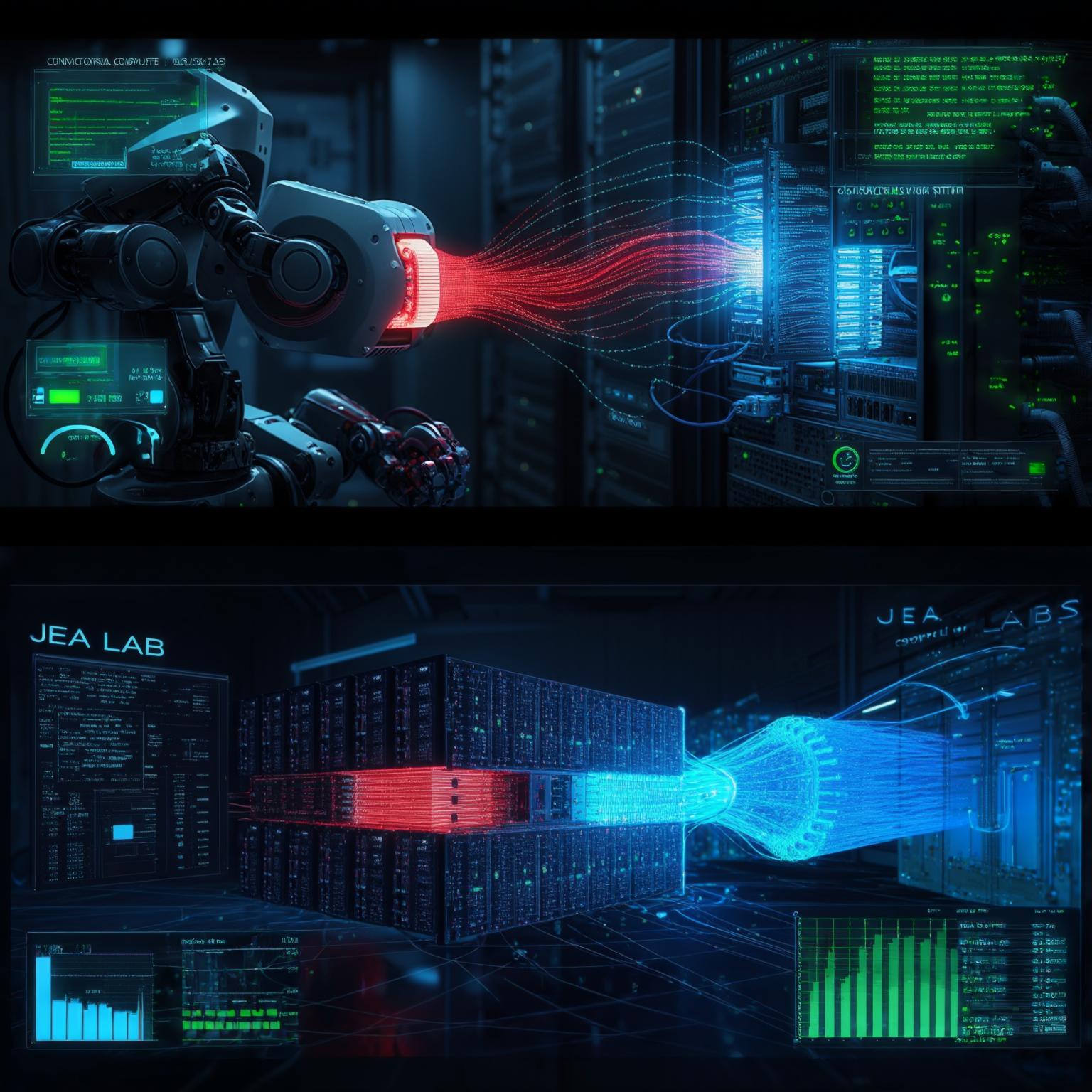

Enter JEA Labs, a revolutionary technology company that's breaking these barriers with the most powerful, efficient, and dense computing systems ever developed. While robot manufacturers focus on mechanical designs and physical capabilities, JEA Labs provides the computational "brains" that unleash their full potential.

Computational Density: The JEA Advantage

JEA Labs manufactures the most powerful computing systems in the world in terms of computational density (Petabytes/Petaflops/TBPS) and energy efficiency (PUE=Power Usage Effectiveness). When integrated with robotics systems, these computational powerhouses transform what's possible:

For robotics manufacturers and integrators, these advantages enable:

- On-board AI processing that eliminates latency and cloud-dependency in robotic systems

- Multi-modal sensor fusion processing at unprecedented speeds for real-time environmental awareness

- Complex motion control algorithms running at frequencies impossible with traditional computing

- Extended operational time for battery-powered robotic platforms due to dramatically lower power consumption

- Compact integration that allows advanced computing in size-constrained robotic form factors

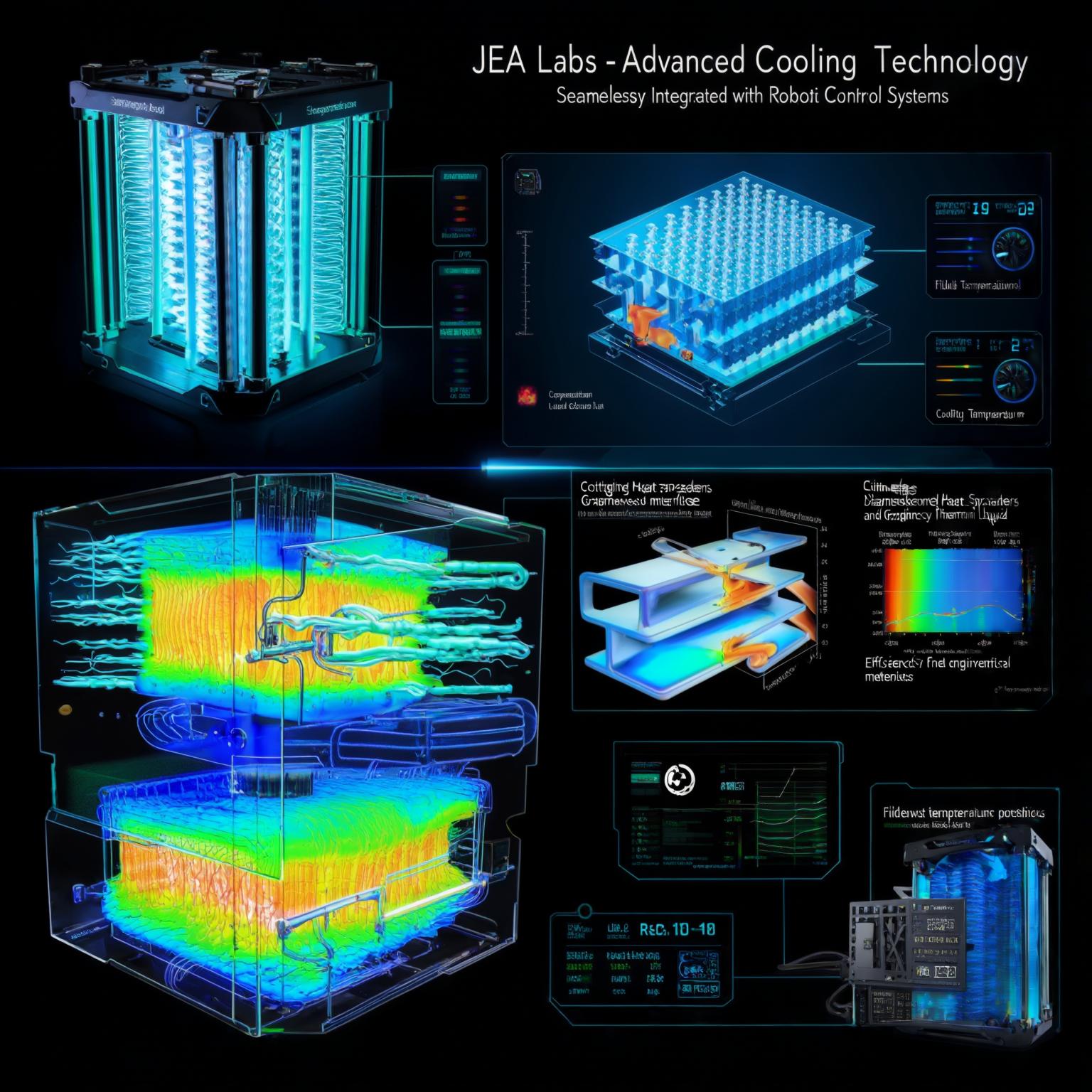

Revolutionary Cooling for Computational Systems

Heat dissipation has always been the Achilles' heel of both high-performance computing and robotics control systems. Traditional cooling solutions for computational components are bulky, inefficient, and inadequate for the processing demands of advanced robotics.

JEA Labs has developed revolutionary cooling technologies for their computing systems that overcome these limitations:

- Water cooling systems achieving PUE of 1.07-1.20

- Engineered liquid cooling systems with extraordinary PUE of 1.01-1.06

- Cooling systems with N+1 redundancy ensuring uninterrupted operation

- Compact design that integrates seamlessly into robotic control systems

- Advanced materials for superior thermal management

When integrated into robotic control systems, these cooling advances enable sustained peak computational performance during intensive operations like real-time mapping, visual processing, or complex kinematics calculations, all while dramatically reducing energy consumption.

Specialized Computing Solutions for Robotics

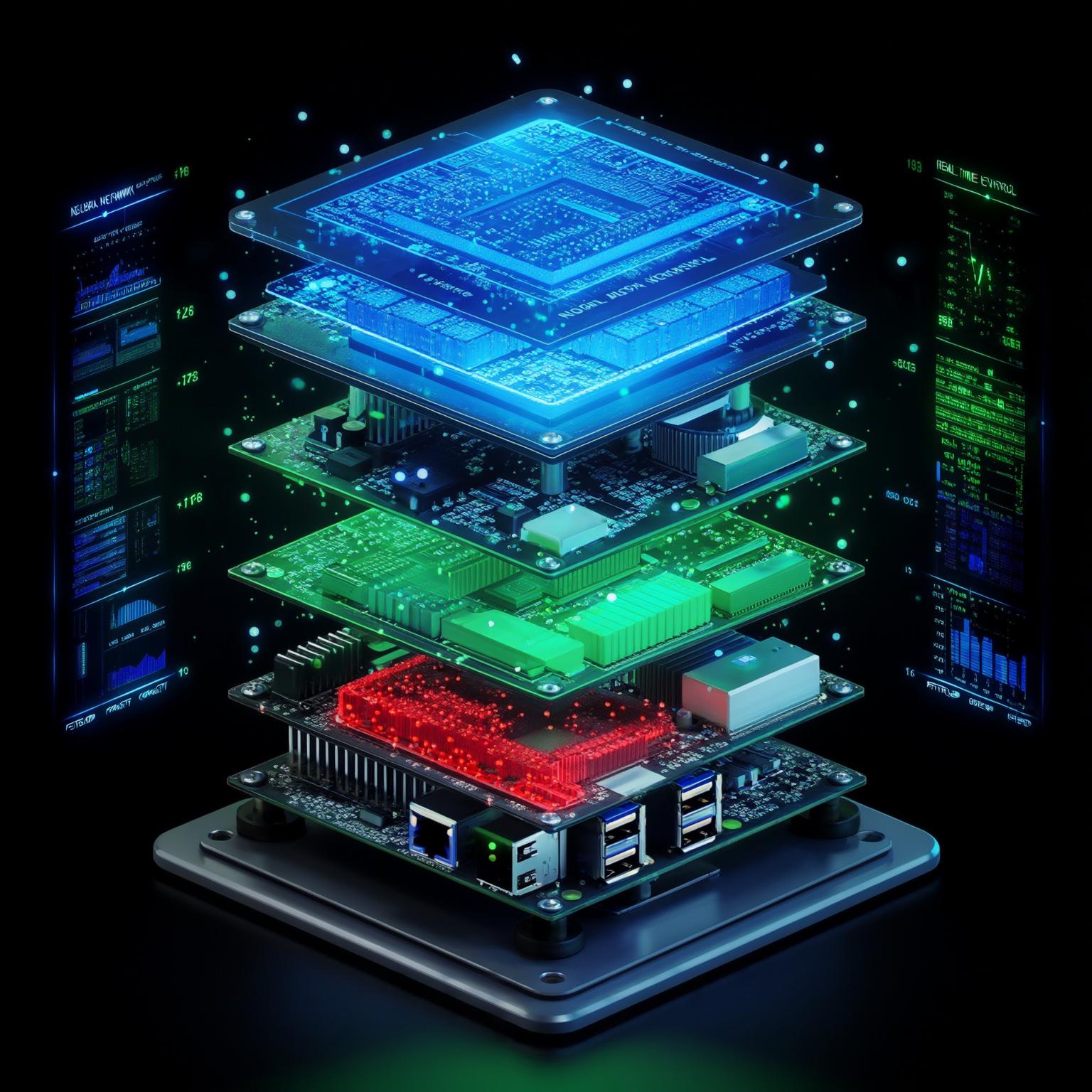

JEA Labs offers a range of computing nodes optimized for integration with different robotics applications. Each computational solution is designed to address specific challenges in robotics control and processing:

Navigation Computing Core

- Multiple SDR antennas for communication and positioning integration

- Redundant GPS/GNSS chips with atomic clocks for precision localization

- 15-20+ RF PCIe cards for sensor signal processing

- 4-8+ GPUs for real-time SLAM and path planning algorithms

- 16-64+ TB RAM for environmental model processing

- Multi-vendor AI accelerators for framework-specific optimization

Sensory Processing System

- 5-6+ GPU/FPGA accelerator cards for parallel sensor data processing

- 2-3+ FPGA Network Cards for high-speed sensor integration

- 16-64+TB RAM for multi-modal sensor fusion algorithms

- 1000-4000+TB storage for sensor data recording and analysis

- Custom software stack optimized for robotics sensory processing

- Supports simultaneous processing of LIDAR, camera, radar, and other sensor inputs

Motion Control Computing

- 5-100+TB RAM with CXL support for complex kinematics modeling

- 300-2000+ processing cores for real-time parallel control algorithms

- Ultra-low latency I/O for actuator signal processing

- Optimized for deterministic computation with microsecond precision

- Support for processing up to 128 synchronized axes of motion

- Custom BSD OS with real-time extensions for precise timing

Vision & AI Computing Platform

- 1-4+ high-performance EPYC/Xeon/Ampere processors

- 16-64+ TB RAM for massive dataset processing

- 10-25+ GPU/FPGA cards for real-time visual processing

- Optimized for neural network inference with sub-millisecond latency

- Supports all major vision and deep learning frameworks

- Scalable architecture compatible with distributed robotic systems

These specialized computing platforms can be integrated with robotics systems from any manufacturer, enhancing their capabilities while maintaining their original mechanical and physical designs. JEA Labs partners with robotics companies to incorporate these computational solutions into existing and new robotic platforms.

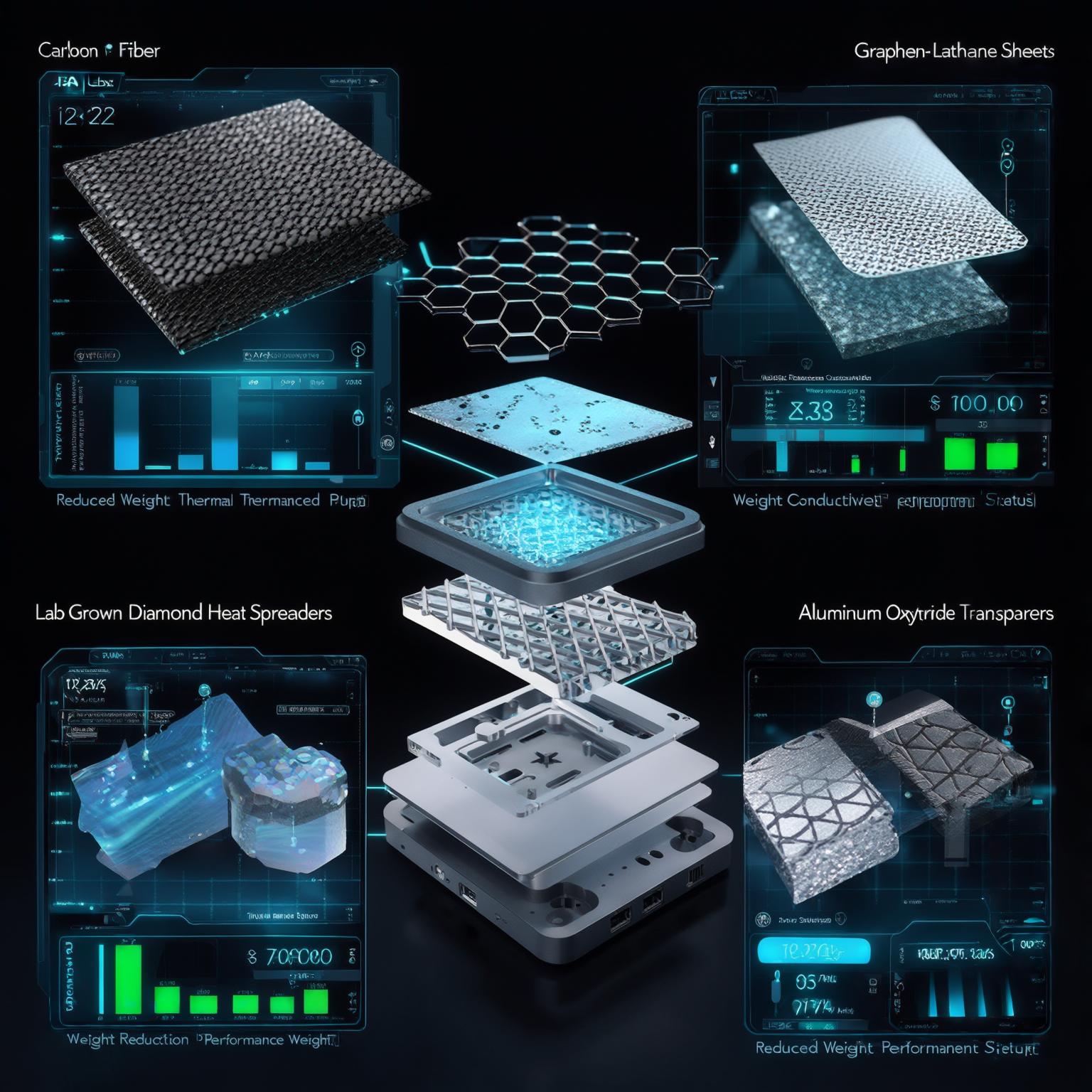

Materials Science & Form Factor Optimization

Beyond raw computational power, JEA Labs' innovation in materials science addresses another critical limitation for robotics companies: the weight and size constraints of onboard computing.

JEA Labs employs exotic and advanced materials in their computing systems, which allow:

- Reducing computational unit weight by 30-60%

- Thermal interfaces for efficient heat distribution

- Unparalleled thermal conductivity

- Utilizing advanced materials exhibiting superior impact resistance, minimal mass, inherent fire resilience, and elevated thermal capacity

For robotics applications, these material innovations translate directly to lighter computational units that can be integrated without compromising payload capacity or mobility. Robotics manufacturers can incorporate JEA systems and still maintain their design parameters for weight distribution and power requirements.

Furthermore, the longevity of JEA systems (7-10+ year lifecycles) aligns perfectly with industrial robotics deployment timelines, ensuring consistent computational performance throughout a robot's operational life.

Software Integration & Robotics Compatibility

JEA Labs doesn't just provide hardware. For each computing system, they dedicate 200-400 hours of configuration and setup, creating tailored software environments that seamlessly interface with robotics control systems:

- Custom-compiled BSD operating systems optimized for deterministic computing needs

- Real-time extensions and kernel modifications for microsecond-precise timing

- Pre-configured interfaces for common robotics control systems (ROS2, YARP, OROCOS)

- Monitoring systems (Grafana, Zabbix, Nagios) configured for computational diagnostics

- Software-defined storage with fault-tolerant distributed filesystems (ZFS, Gluster, Ceph)

- Security hardening for industrial deployment environments

This level of software integration ensures that JEA Labs computing systems don't just offer raw computational power, but deliver it in a form that integrates seamlessly with the robotics manufacturer's existing control architectures. Robotics companies can maintain their proprietary control software while leveraging JEA's computational capabilities.

Technical Specifications for Robotics Computing

| Parameter | STARTING/BASIc Integration | OUR Advanced Integration |

|---|---|---|

| Processing Cores | 300-500 cores | Up to 2000+ cores |

| Memory Capacity | 1-8TB RAM | Up to 100+TB with CXL |

| Storage Capacity | 500-1500TB | Up to 4000+TB |

| AI Acceleration | 4-8 GPU/FPGA cards | Up to 25+ specialized cards |

| Network Throughput | 25-100 GBE | Up to 800+ GBE |

| Power Efficiency | PUE 1.07-1.20 (water) | PUE 1.01-1.06 (engineered liquid) |

| Weight Reduction | ~30% vs conventional | Up to 60% vs conventional |

| Base Price Range | Starting at $175k | $4.5-6 million (full spec) |

These specifications represent the computing capabilities that JEA Labs can provide to robotics manufacturers and integrators. Each system is fully customizable to meet the specific computational requirements of any robotic platform, regardless of manufacturer or application domain.

Integration with Robotics Applications

Industrial Manufacturing Enhancement

JEA Labs' computing systems can transform conventional industrial robots by providing the computational power needed for real-time adaptive control. When integrated with existing robotic arms, JEA systems enable processing of sensory data from multiple modalities simultaneously, allowing robots to adjust operations in microseconds based on material variations or environmental changes.

Autonomous Systems Acceleration

For companies developing mobile robots and autonomous vehicles, JEA computing solutions provide unprecedented sensor fusion capabilities. By integrating JEA systems into their platforms, robotics manufacturers can process data from LIDAR, cameras, radar, and other sensors in real-time while running complex SLAM algorithms locally without cloud dependency.

Medical Robotics Precision

Surgical and medical robotics demand both extreme precision and real-time adaptability. JEA Labs' ultra-low-latency computing systems can be integrated with surgical robots to enable haptic feedback, tremor compensation, and computer vision at unprecedented speeds, improving patient outcomes while reducing surgeon fatigue.

Advanced Robotics Research

For companies and institutions developing next-generation humanoid or specialized robots, JEA's compact, efficient computing platforms provide the computational foundation needed for advanced capabilities. These systems can be integrated into existing robot designs to dramatically enhance their sensing, planning, and interaction capabilities.

Unified Platform for Data-Intensive Research & AI

Our Software-Defined Platform delivers a highly versatile, end-to-end solution for advanced research and AI workloads. It provides inherent operating environment agnosticism, enabling seamless deployment of diverse software stacks including all major ML frameworks and a vast ecosystem of open-source scientific applications. Engineered for comprehensive data acquisition, the system supports hyper-dense integration and exponential scaling of a multitude of sensor inputs via standard, high-bandwidth interfaces, catalyzing unprecedented efficiency and capability for large-scale data vision, analysis, and processing initiatives.