From Chip to Atmosphere: The Heat's Journey

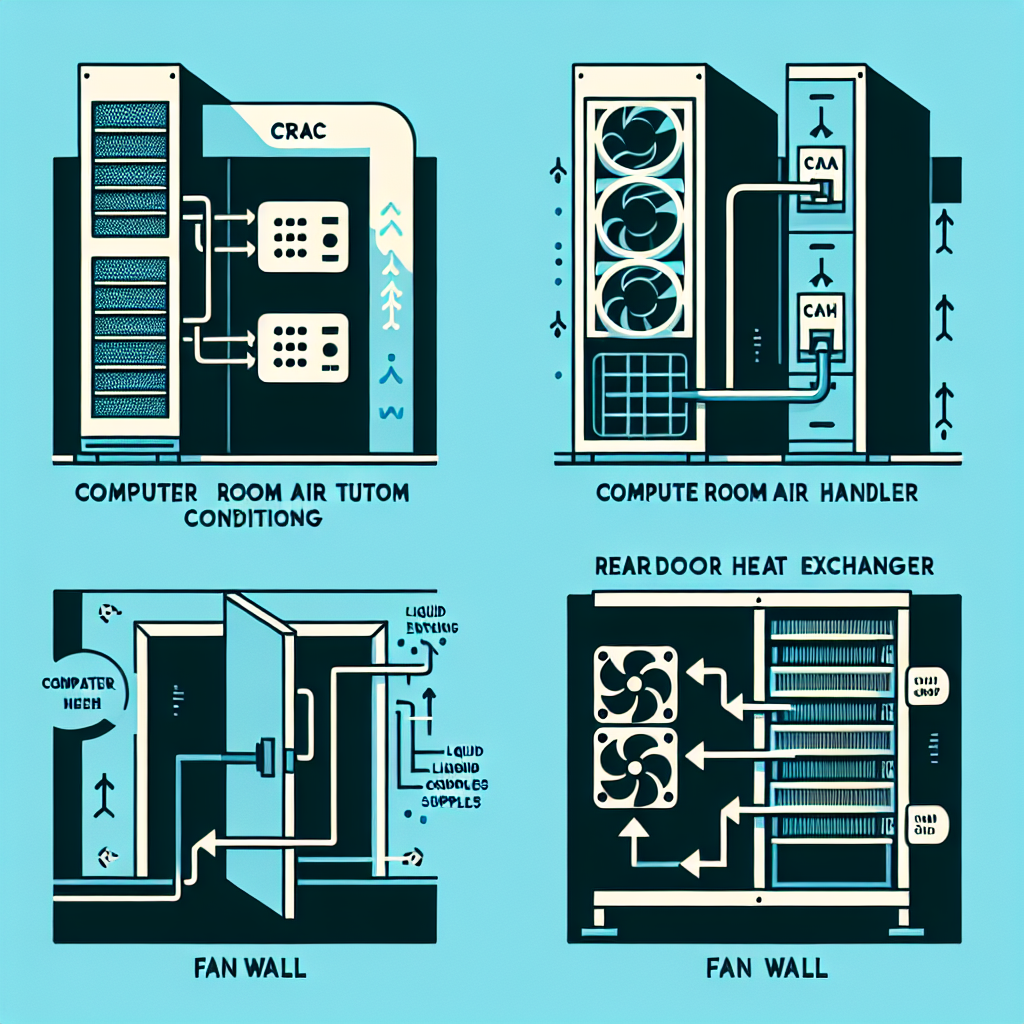

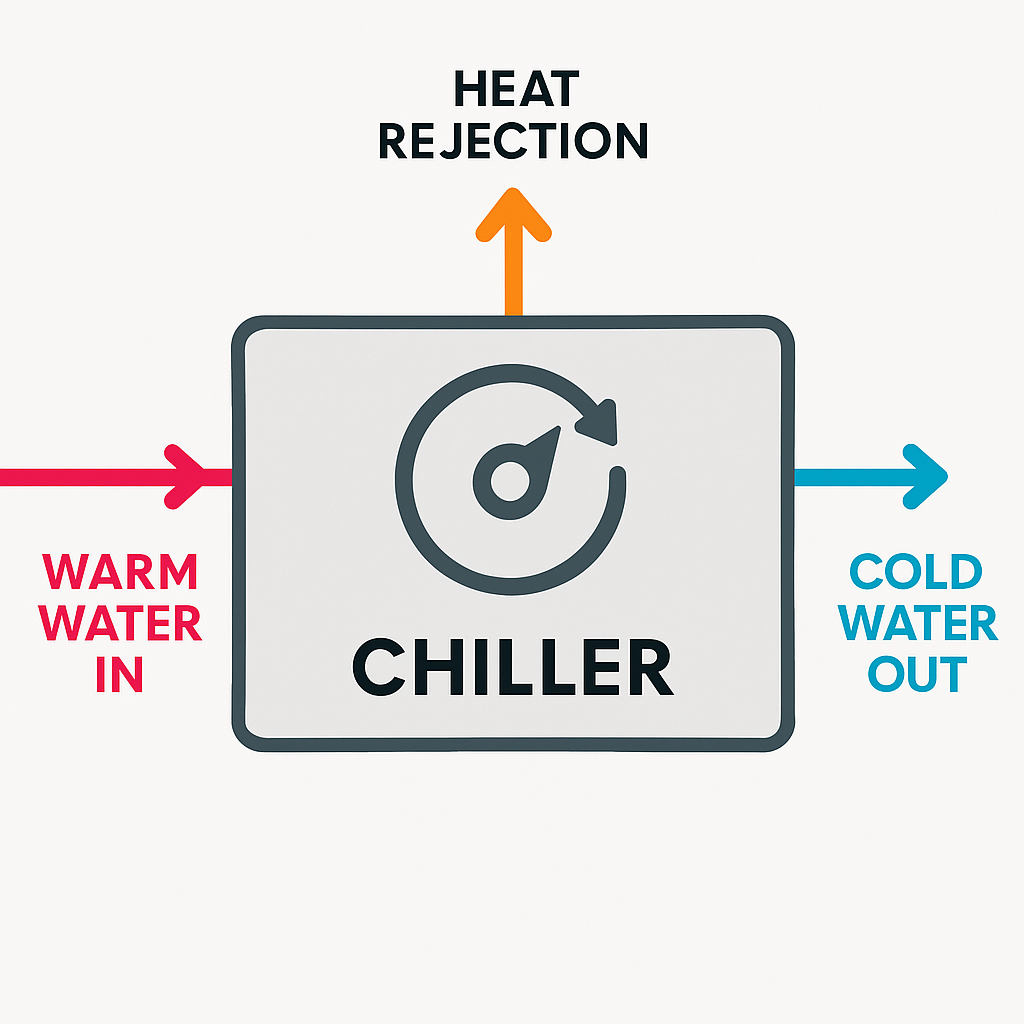

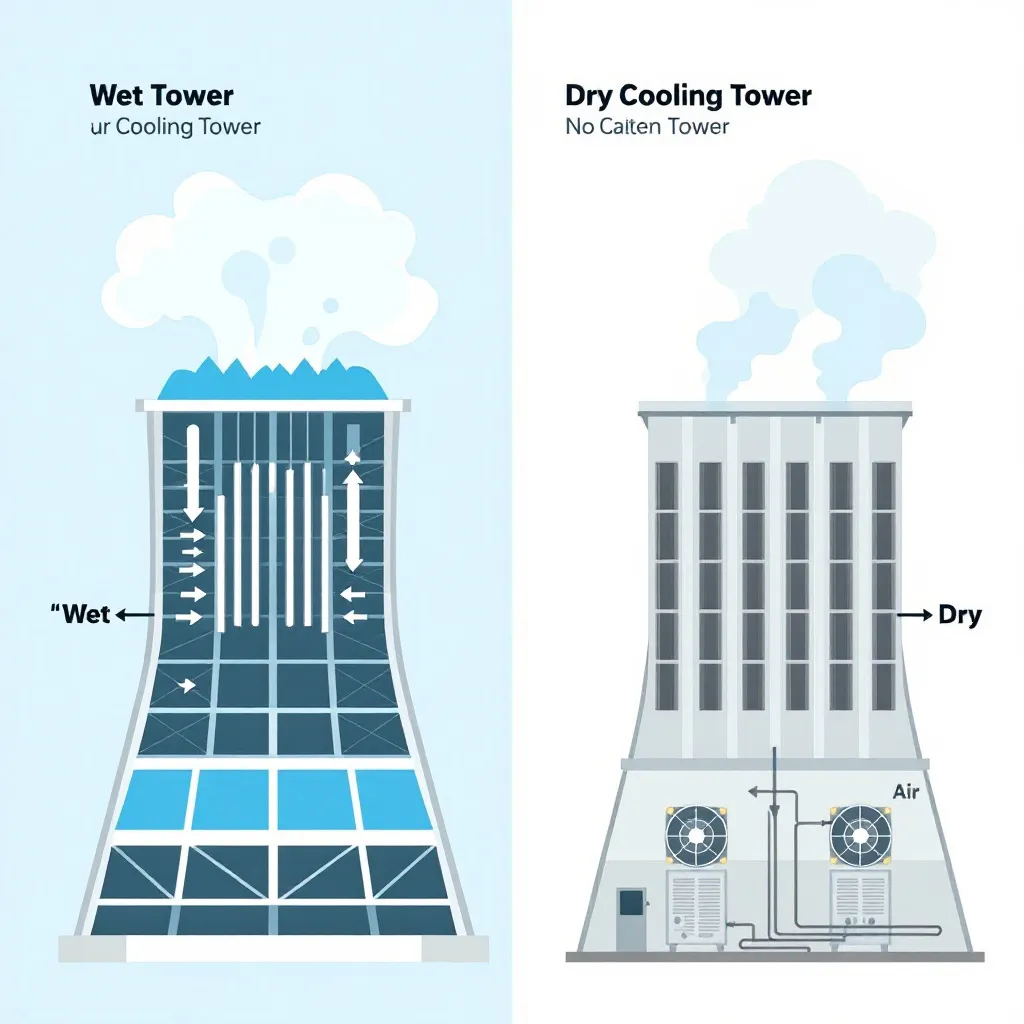

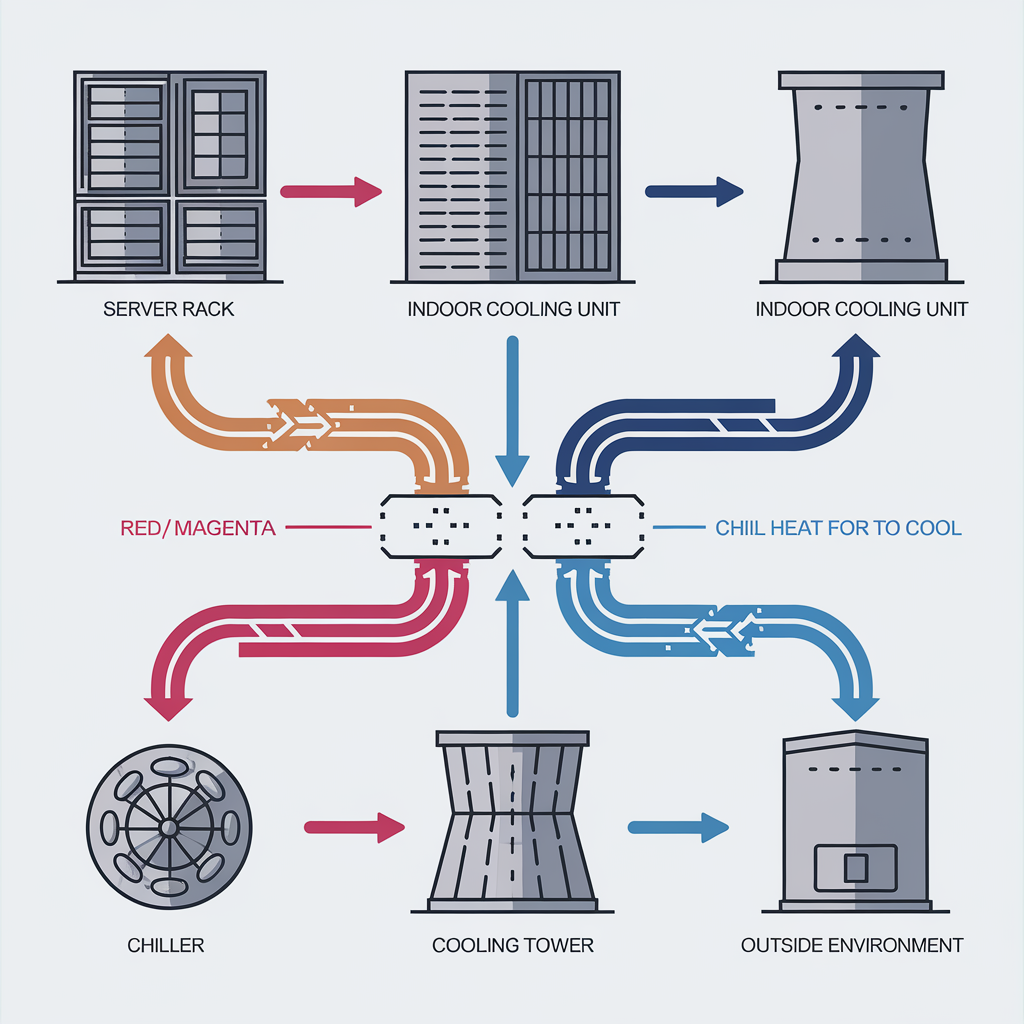

Having established the critical nature of datacenter cooling in the age of AI, this article delves into the mechanics of traditional cooling systems. These air and water-based technologies form the backbone of today's digital infrastructure, representing sophisticated engineering solutions developed over decades to manage ever-increasing thermal loads.

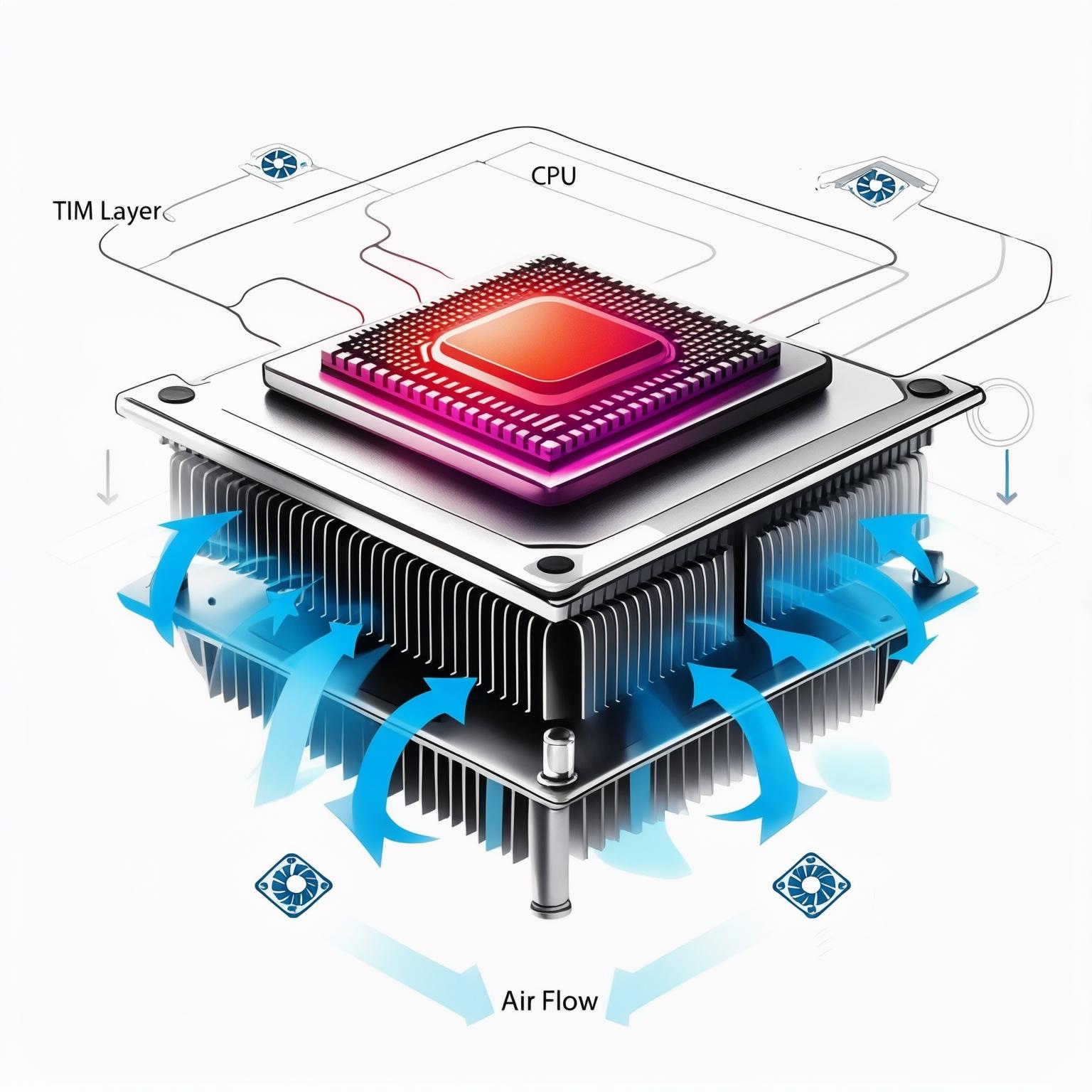

Understanding the components and the pathway heat takes from the server chip all the way to the outside environment is fundamental. We'll trace this journey through the core systems that maintain the operational temperature of hyperscale facilities.

Heat travels through multiple stages to exit the facility.