System Breakdown: Anatomy of Robotic Units

Deconstructing Robotic Systems

Following our analysis of the global robotics revolution in Part 1, we now perform a deep dive into the core: what constitutes a robot and the different forms automation takes today. Robotics is fundamentally a complex systems engineering challenge—integrating hardware and software to replicate or exceed human work capabilities. This requires meticulous design and rapid iteration to achieve the necessary precision and reliability.

The goal is to create machines capable of adding labor capacity (24/7, high throughput) with lower attrition. This merging of mechanical function with software intelligence is bringing us closer to expanding industrial and service economies beyond human physical constraints. While the concept of "Embodied AI" operating autonomously captures the imagination, the reality involves intricate hardware components working in concert with sophisticated software.

// System Status: Robotic Architecture Overview.

Classifying Robot Types: From Fixed to Mobile

The robotic landscape is increasingly diverse. Robots are often categorized by their form factor, capabilities, and intended environment. Understanding these types is key to grasping the current state of automation deployment.

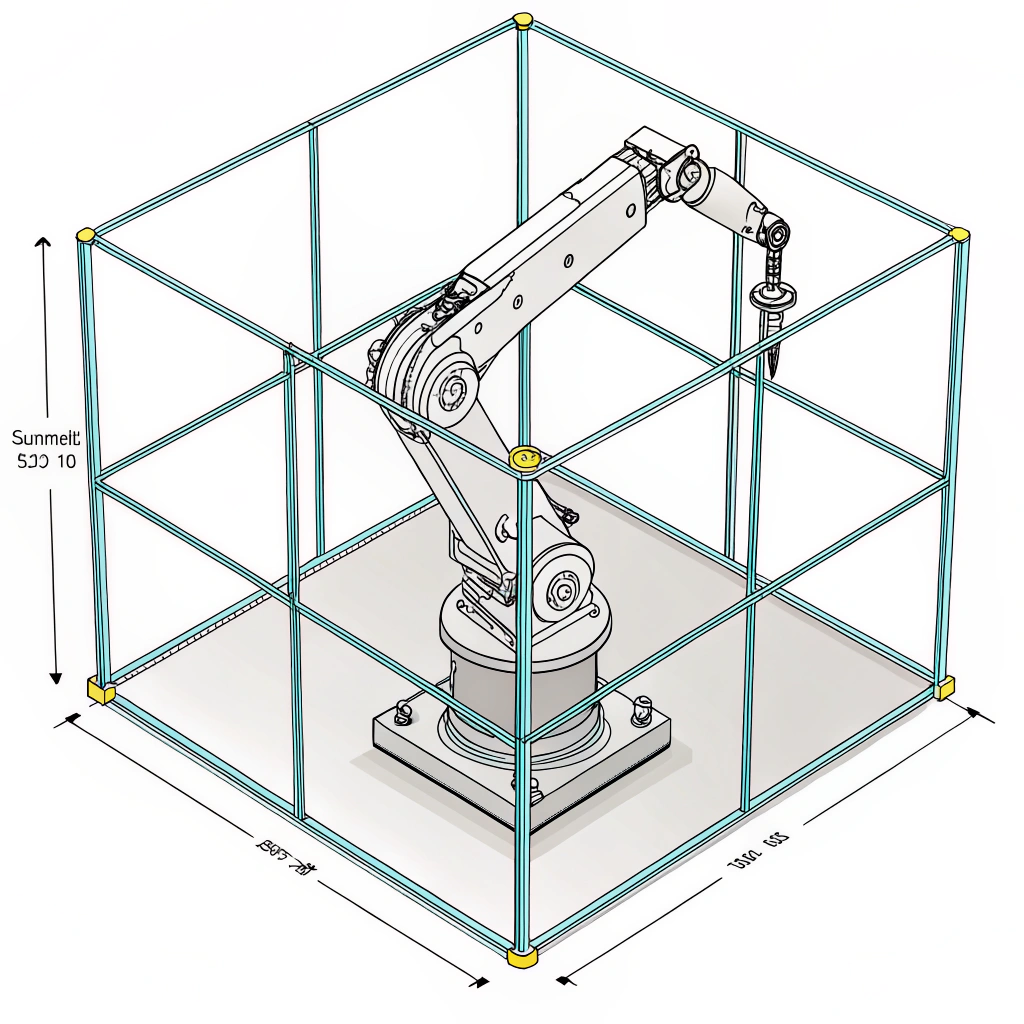

Industrial Robots

Traditional robots prioritizing speed, precision, and payload in structured industrial environments (automotive, electronics). Typically fixed in isolated safety cells due to lack of flexibility and human safety concerns.

- > High Speed / Precision

- > High Payload Capacity

- > Fixed Location

- > Structured Environments Only

- > Requires Safety Cages

Collaborative Robots (Cobots)

Designed to work alongside humans. Trade-off: lower payload/speed for higher safety (sensors), flexibility, and easier programming. Used for less demanding tasks in factories, often assisting other machines like CNCs.

- > Human-Safe Interaction

- > Flexible & Reprogrammable

- > Lower Payload/Speed

- > Sensor-Rich (Force, Vision)

- > Easier to Deploy/Retask

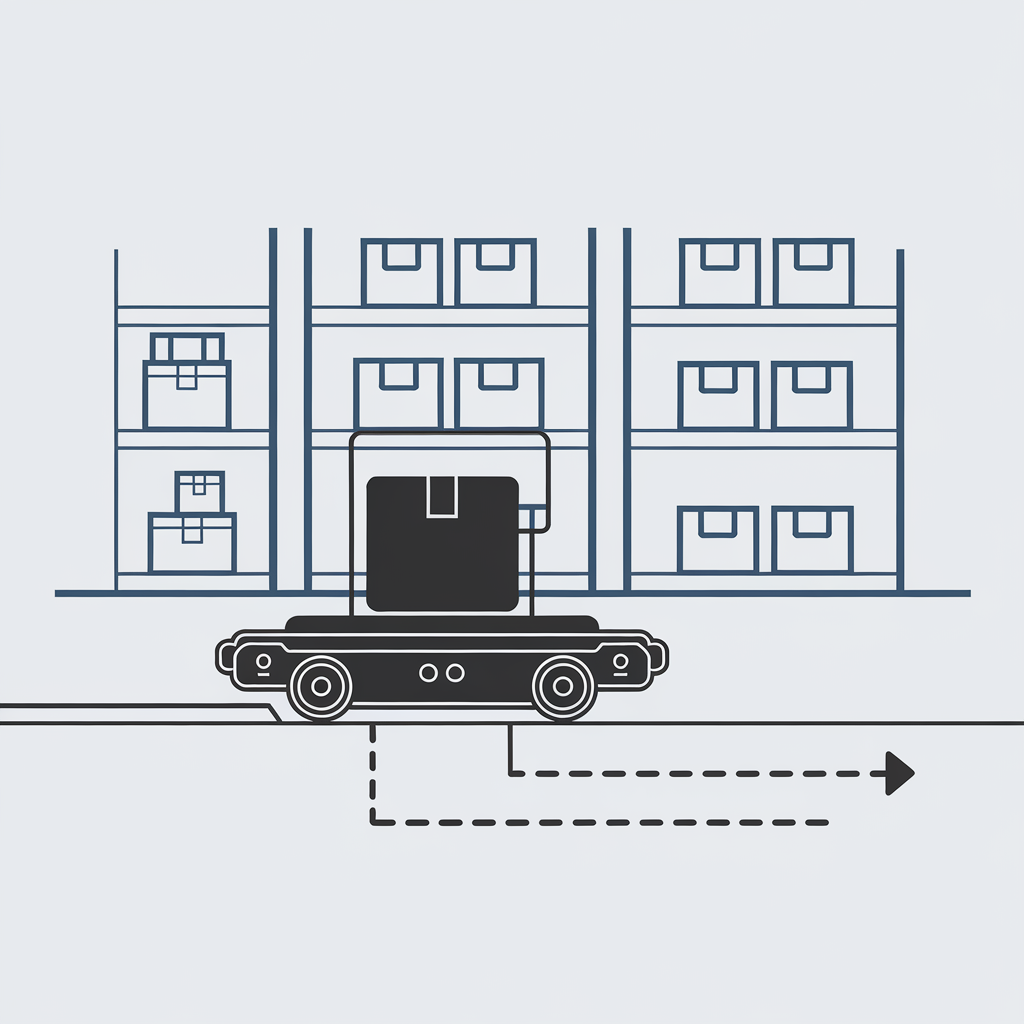

Mobile Robots (AGVs)

Early mobile form factor primarily for transportation. Requires fixed guidance (lines, beacons) on the floor. Simple task execution (move object A to B). Rigid in navigation.

- > Transportation Focus

- > Requires Guided Path

- > Widely Deployed (Warehouses)

- > Simple Task Execution

- > Limited Navigation Flexibility

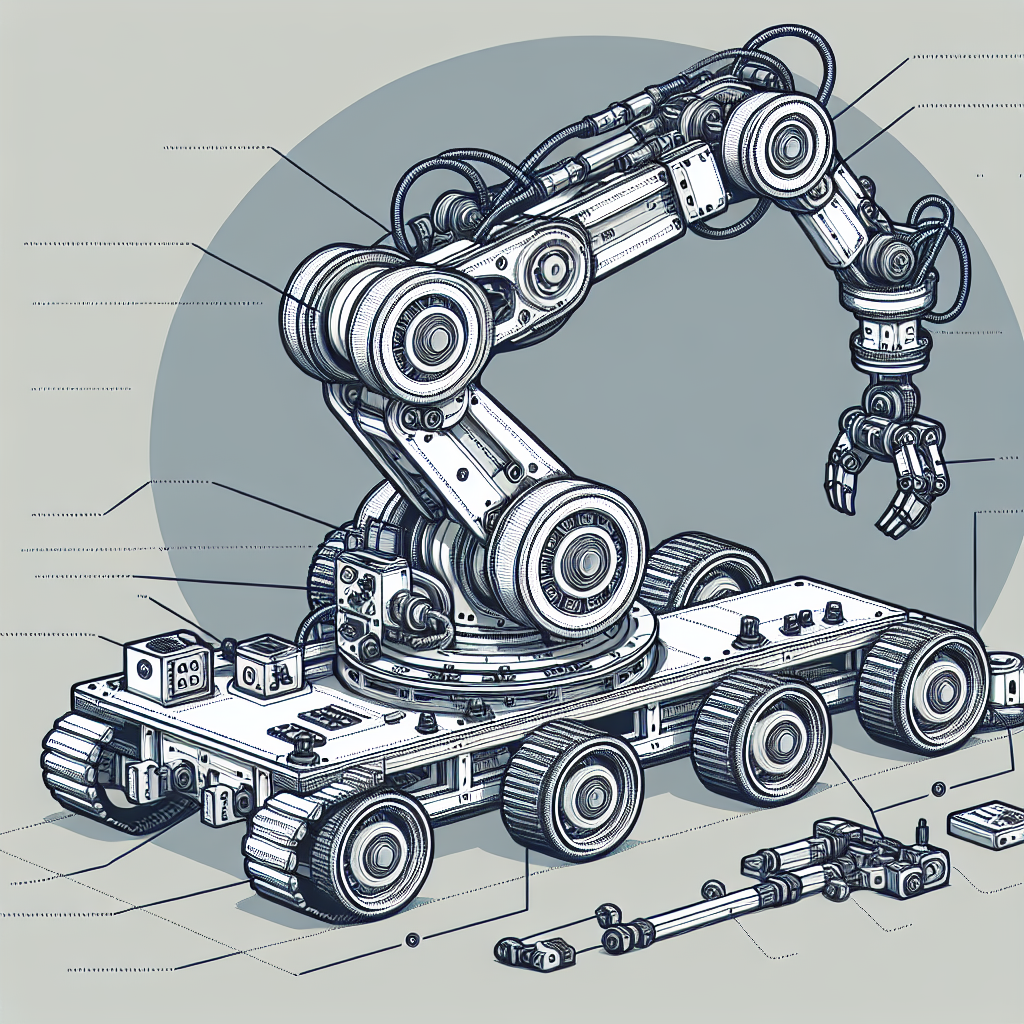

Mobile Manipulators

Robotic arms mounted on mobile bases (often wheeled). Combine manipulation with short-range navigation. Primarily found in factory settings with flat floors for grasping and moving objects between stations.

- > Combines Mobility & Manipulation

- > Wheeled Base Common

- > Short-Range Navigation

- > Used in Structured Env. (Factories)

- > Early Deployment Phase

Quadrupeds

Four-legged mobile robots designed for navigation in more unstructured or uneven outdoor/complex environments (construction sites, inspection). Still largely in prototyping and early deployment phases.

- > All-Terrain Mobility

- > Inspection/Exploration Focus

- > Dynamic Balancing

- > Less Structured Env. Potential

- > Prototyping Phase

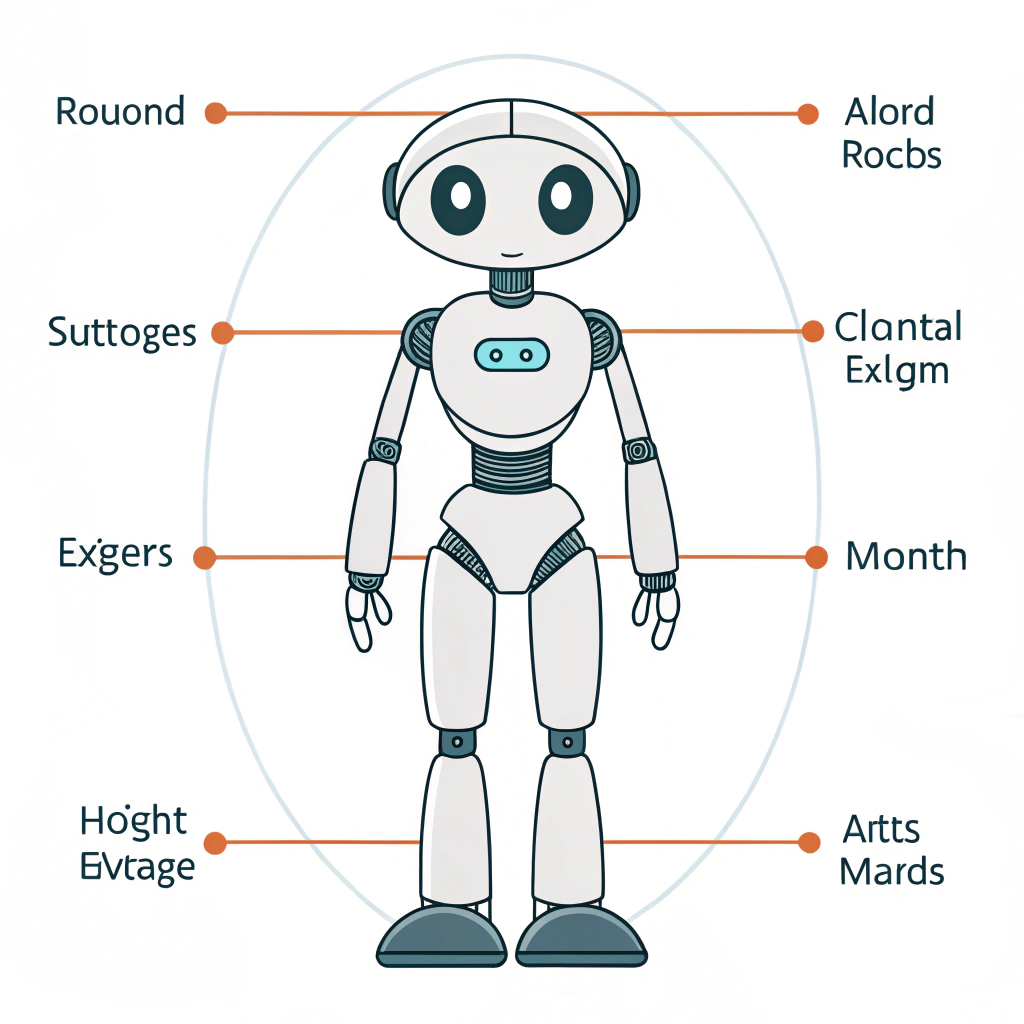

Humanoids

Robots with human-like form factor (two arms, two legs). Poised for functional operation in human-populated domains. High degrees of freedom, aiming for versatile tasks. Currently in early production, not yet integrated into formal settings at scale.

- > Human-Like Form Factor

- > High Degrees of Freedom

- > Human-Populated Env. Target

- > Complex Manipulation Potential

- > Early Production Phase

// Data Log: Identified Robot Form Factors and Capabilities.

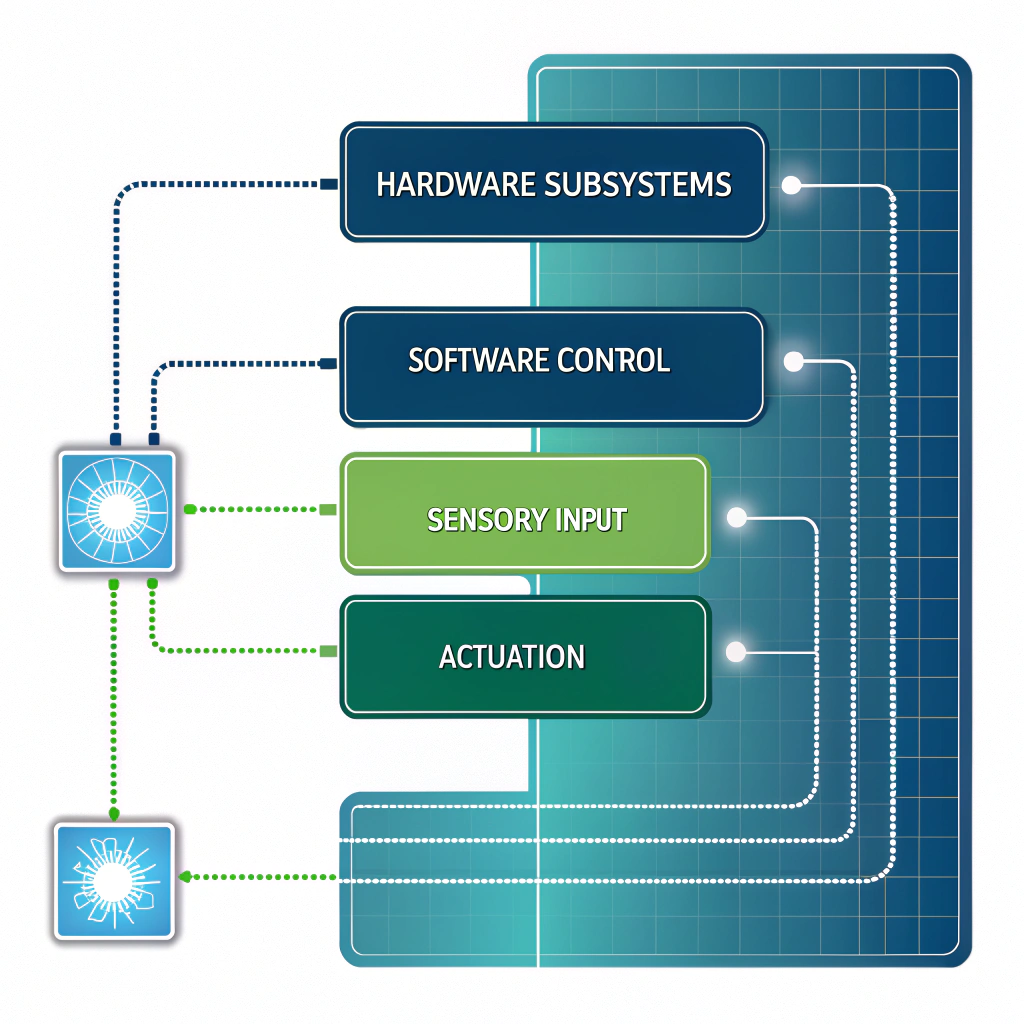

Hardware Components: The Robot's Anatomy

A robot is an assembly of sophisticated hardware components working together. The supply chain for these parts is globally dispersed, with noticeable concentrations of expertise and manufacturing capacity outside the United States.

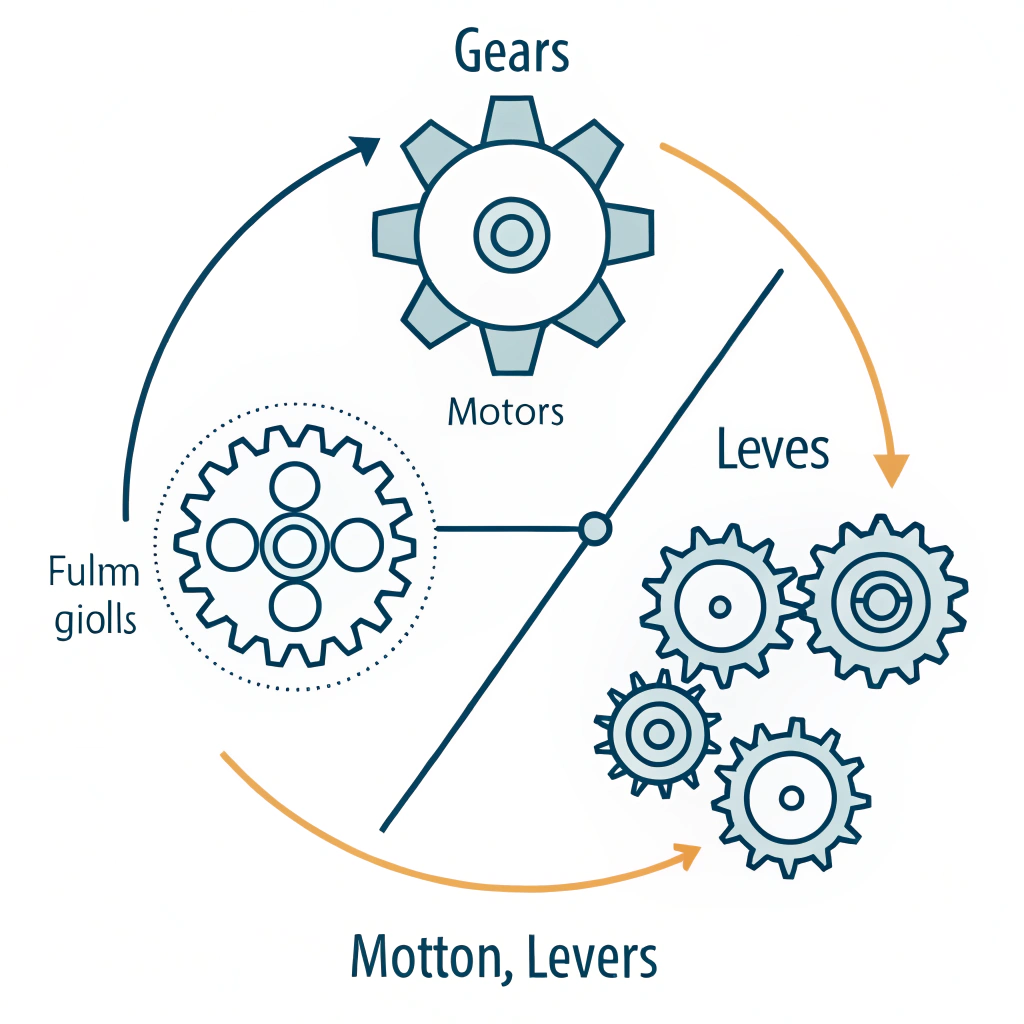

Actuation & Motion

Components responsible for generating physical movement.

- > Actuators / Motors (Servo motors common for precision)

- > Drives (Regulate power to motors)

- > Gearboxes (Increase torque, precision; e.g., Harmonic Drive)

- > Permanent Magnets (Crucial for efficient motors; often Neodymium)

Control Systems

"The Brains" - Process data and control actions.

- > Microcontroller Units (MCUs) / Embedded Systems (Low-level control)

- > Programmable Logic Controllers (PLCs) (High-level sequencing)

- > Control Circuits / Feedback Mechanisms (Part of servo motors/drives)

Sensing & Perception

Allow the robot to understand itself and its environment.

- > Cameras (2D, 3D Depth)

- > LiDAR (Detailed spatial mapping)

- > Joint Encoders (Joint position/speed)

- > Tactile/Touch Sensors

- > Proprioceptive Sensors (Internal state)

- > Force-Torque Sensors (Interaction forces)

End-Effectors

The tools or 'hands' at the end of the robot arm.

- > Grippers (Basic or dextrous - ongoing R&D)

- > Welding Torches, Paint Sprayers, etc.

- > Specific tools for tasks

- > Payload Capacity is key

Power Systems

Providing energy for operation, especially for mobile robots.

- > Batteries (Lithium-ion common for mobile)

- > Power Supplies / Connectors

Structure & Materials

The physical body and base materials.

- > Chassis / Frame

- > Joints / Links

- > Metals, Plastics, Composites

- > Raw Ores & Processed Minerals (e.g., Copper, Cobalt, Nickel)

// Data Log: Hardware Component Inventory. Supply Chain Analysis Required (See Part 3).